FREE Next Working Day or Saturday delivery on orders over £150 - Choose option in basket

(UK mainland, excludes Highlands rural areas, order before 3pm. Saturday delivery option available from 3PM Thursdays.)

Hempel Silic Seal Conversion Primer

£ 34.95 - £ 84.95

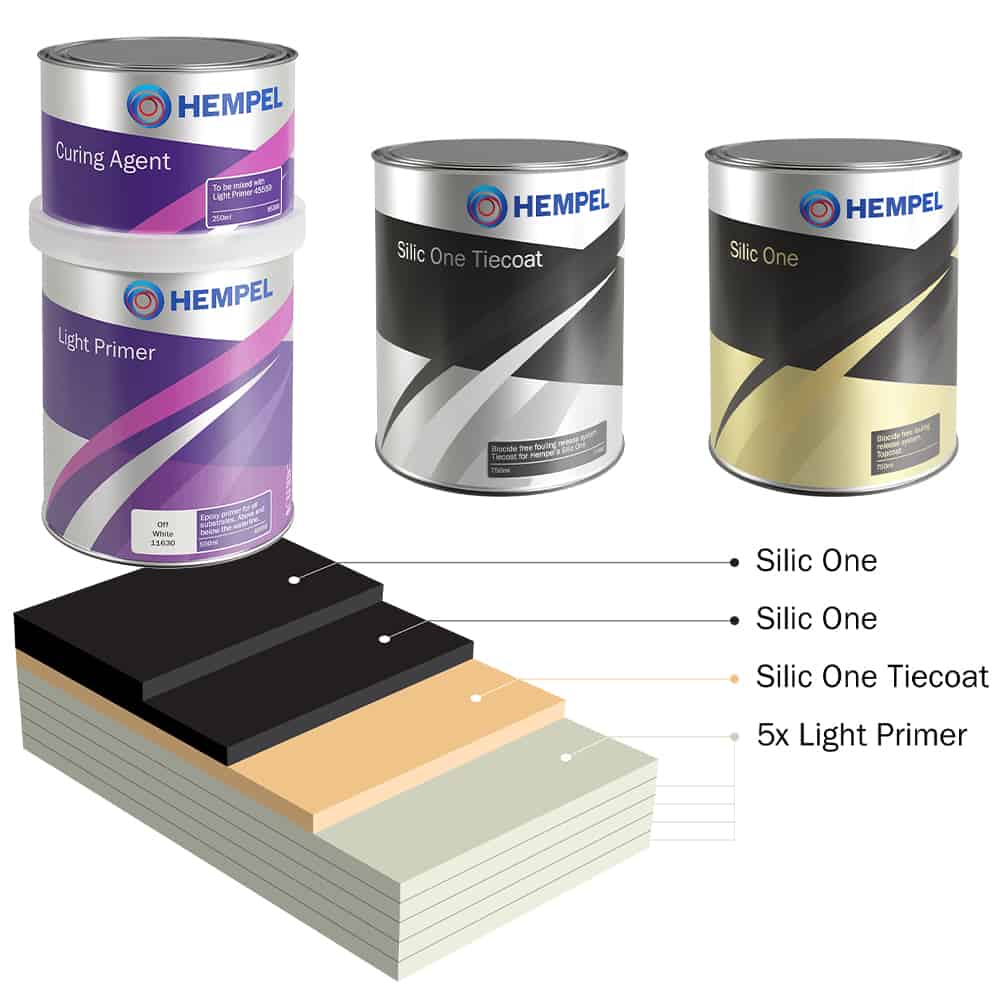

Hempel Silic Seal Conversion Primer – Part of the Silic One system

Hempel’s Conversion Primer is a two-component epoxy to enable easy conversion from antifouling to Hempel’s advanced biocide-free fouling protection. Can be applied on previously painted antifouling in good condition..

What is Hempel Silic One?

Hempel Silic One is a biocide-free antifouling solution based on silicone and hydrogel. This gives the coating surface water-like properties, making it difficult for fouling organisms to attach to the hull and easy for them to be removed when the boat is in motion.

PLEASE NOTE: There are strict timings from overcoating to immersion time that must be followed during the application process. If these are not followed the product may not perform correctly. This includes using the correct primers and tie-coats. See Hempel’s Silic One application guide.

Specifications for Silic Seal Conversion Primer

Theoretical spreading rate: 15 m² per L (11.25m² per 750ml tin) – Thinning is not allowed

Cleaner: Hempel’s Thinner 845 (Cleaning only)

Application tool: Brush or Roller

Pot life: 8 hours at 20ºC

Surface temperature must be above 10ºC during application and curing.

Be aware that the product has a very low viscosity and any runs and sags should be brushed out immediately.

How is Silic One different from traditional antifoul?

Traditional antifouling works by releasing a range of bioactive ingredients that prevent organisms such as barnacles, slime and weeds from attaching to the vessel. This obviously has an environmental impact.

Hempel Silic One is biocide-free therefore much better for the environment. It gives the coating surface water-like properties, making it difficult for fouling organisms to attach.

Regardless of which style of antifoul you choose, keeping your hull free from fouling is important as a smooth hull will have less drag therefore using less fuel and decreasing fuel emissions.

The Silic One system comprises of various primers, tie coats and top coats depending on the application you require.

Advantages of using Hempel Silic One

Biocide and copper free

Probably the most important advantage is that it is biocide free, therefore better for the environment.

2 years of protection and easy maintenance

Maintenance of Hempel’s Silic One is easy and simple. Maintenance cost is lower compared to traditional antifouling. In order to maintain the system, a new layer of Hempel’s Silic One should be applied every second year. The Silic One System performs more effectively if the boat remains in the water. If the boat is used in areas of high environmental conditions, or kept out of the water for an extended period, it may be necessary to apply a new layer of Hempel’s Silic One every year.

Use on all hull materials including metal

Most traditional antifoul can not be applied to metal hulls due to the copper content. So you have to use a specific specialist antifoul such as International Cruiser 200 Antifouling. Silic One can be used on almost any boat hull or propeller.

The system can be used over old antifouling

If the existing antifoul is in good condition you can apply the Silic One system on top. Just make sure you follow the correct procedure using the relevant primers and tiecoat.

Silic One applications

Silic One can be used in most applications, whether it be on a new hull or on a previously antifouled boat. You just need to follow the correct procedure. See Hempel’s Silic One application guide.

Things to consider when making the switch to Hempel Silic One

Application is all about timing! There are strict timings from overcoating to immersion time that must be followed during the application process. If these are not followed the product may not perform correctly. This includes using the correct primers and tie-coats. See Hempel’s Silic One application guide.

Once Silic One and Tie-Coat tins are opened they must be used within 60 minutes. A tin that has been opened cannot be stored for later use. So it is important to purchase the correct amount for your job.

Silic One has a shelf life which unopened tins must be used before. Remember to check this before application.

Painting should be avoided if there is a risk of rain. The paint is also sensitive to humidity, therefore only open the tin just before use. It is also advisable to put the lid back on between pours into a paint tray. Don’t forget you have 60 minutes to use the whole tin.

It is strongly advised to apply the maximum film thickness without sagging for best performance and adhesion.

The boat can be launched in 24-36 hours after the last coat has been applied. Maximum time to launch is 1 month.